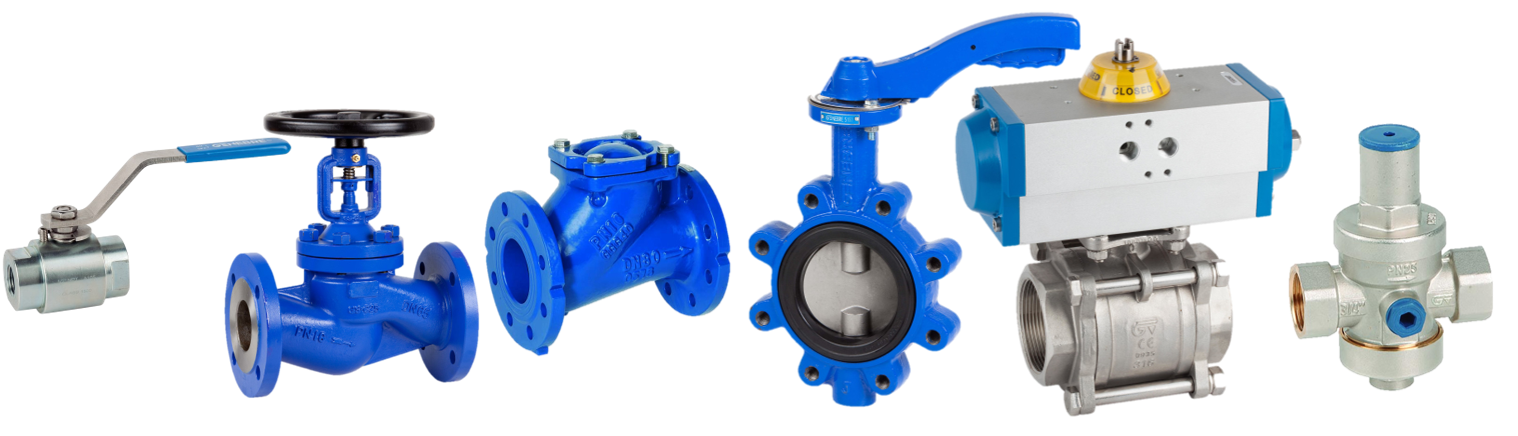

Our GENEBRE products serve a wide range of industries, such as water treatment, HVAC, chemical, pharmaceutical, and food processing. The valves are typically made from materials like stainless steel, brass, and various alloys, offering durability and reliability in various applications.

The main products include:

- Ball valves

- Globe valves

- Check valves

- Butterfly valves

- Control valves

- Pressure reducing valves

- Actuators and accessories

GENEBRE offers a range of ball valves that are widely used in industrial applications, including water treatment, HVAC systems, chemical processing, and other sectors that require precise control over fluid flow.

Some of the key ball valve products from GENEBRE include:

GENEBRE BALL VALVES

Key Features

Design:

GENEBRE ball valves come in a variety of designs, including two-way, three-way, and multi-port configurations, providing versatility for various industrial needs.

Materials: These valves are typically made from stainless steel (AISI 316), brass, carbon steel, and other high-quality materials to withstand demanding environments, including corrosion and high-pressure conditions.

End Connections: GENEBRE ball valves come with various types of end connections, such as threaded, flanged, welded, or clamped depending on the installation requirements.

Sealing: The valves typically use PTFE (Teflon) or PPS for sealing to ensure a tight, leak-free operation.

Actuators: Many of GENEBRE’s ball valves can be manually operated or fitted with pneumatic or electric actuators for automatic control.

Some specific ball valve models from GENEBRE include:

1. GENEBRE Type 3100 (Standard Ball Valve)

- Application: Suitable for water, gas, air, and steam applications.

- Materials: Brass or Stainless Steel body, with PTFE seals.

- Pressure Rating: Suitable for pressures up to 40 bar.

- Temperature Range: Typically, these valves can operate within a temperature range of -20°C to 150°C.

- Design: Two-way valve, compact and reliable for general industrial uses.

2. GENEBRE Type 3105 (Flanged Ball Valve)

- Application: Used in larger pipelines where flanged connections are required.

- Material: Stainless Steel (AISI 316) body for corrosion resistance.

- Pressure Rating: Up to 40 bar.

- Temperature Range: Capable of handling temperatures from -20°C to 180°C.

3. GENEBRE Type 3700 (Stainless Steel Ball Valve)

- Application: Designed for harsh environments, such as chemical processing or high-pressure systems.

- Materials: Full stainless steel construction (AISI 316), making it resistant to corrosion and aggressive chemicals.

- End Connections: Flanged, threaded, or welded connections.

- Features: Available with both manual and actuator-operated versions.

4. GENEBRE Type 3080 (Three-Way Ball Valve)

- Application: For diverting or mixing flow in systems that require multiple directions of flow.

- Design: Three-way ball valve, typically used in applications where flow needs to be split or combined between multiple pipelines.

- Material: Stainless steel or brass with PTFE seals.

Applications for GENEBRE Ball Valves

- Water Treatment: Ball valves are ideal for controlling water flow in treatment plants, pumping stations, and distribution networks.

- Chemical Industry: Resistant to aggressive chemicals and high pressures, making them suitable for fluid control in chemical processing.

HVAC Systems: For regulating hot or cold water in heating, ventilation, and air conditioning systems. - Food and Beverage: GENEBRE valves are used in the food industry for applications where hygiene is critical, and the valves must meet strict standards.

(bisa ditambahin foto2 nya)

Benefits of GENEBRE Ball Valves

- Durability: Thanks to the high-quality materials (such as stainless steel), these valves have excellent resistance to corrosion, wear, and high pressure.

- Tight Sealing: GENEBRE ball valves are designed to provide an excellent seal when closed, minimizing the risk of leakage.

- Ease of Operation: The quarter-turn operation makes it easy to open and close, which is ideal for situations requiring quick shutoff.

- Customization: Available in various sizes, materials, and connection types to meet specific industrial needs.

GENEBRE GLOBE VALVE

A globe valve is a type of valve used primarily for regulating flow in a pipeline. Unlike other valve types (e.g., ball or gate valves), a globe valve provides precise flow control and is often used when the flow needs to be adjusted or throttled.

How a Globe Valve Works

A globe valve is constructed with a globe-shaped body, which gives it its name. Inside, the valve contains a movable disc that sits against a seat inside the valve body. The disc is typically controlled by a stem that can be raised or lowered, allowing or restricting the flow of fluid through the valve.

When the valve is open, the disc is lifted away from the seat, allowing fluid to flow through the valve.

When the valve is closed, the disc presses down against the seat, stopping the flow of fluid.

Globe valves are particularly effective for flow regulation because the movement of the disc relative to the seat can finely control the size of the opening, allowing for precise adjustments to the flow.

Main Features of GENEBRE Globe Valves:

- Flow Control: Globe valves are excellent for regulating the flow of liquids or gases because they offer precise throttling and flow control, especially at low flow rates.

- Construction Materials: GENEBRE globe valves are made from stainless steel (AISI 316), brass, carbon steel, and other corrosion-resistant materials, depending on the application requirements.

- End Connections: GENEBRE globe valves are available with various end connections, including threaded, flanged, welded, and clamped options.

- Pressure and Temperature Ratings: These valves are built to handle high-pressure and high-temperature applications, making them suitable for demanding industries.

- Sealing: Most GENEBRE globe valves feature PTFE (Teflon) or PPS seals to ensure a tight shutoff and minimize leakage.

- Manual or Automated Operation: These valves can be operated manually with a handwheel or equipped with pneumatic or electric actuators for automatic control.

Key Components of a Globe Valve:

- Body: The main casing of the valve, where fluid flows through.

Bonnet: The top portion that contains the stem and helps hold the valve together. - Stem: A shaft that connects the valve disc to the actuator or handwheel. The stem moves up or down to control the valve's opening and closing.

- Disc: The part that seals the flow path by resting against the valve seat when the valve is closed.

- Seat: The surface where the disc rests to create a seal when the valve is closed.

- Handwheel/Actuator: The manual or motorized mechanism used to move the stem and control the valve.

Types of GENEBRE’s Globe Valves

GENEBRE offers several types of globe valves based on their application, design, and functionality:

1. GENEBRE Type 5100 (Standard Globe Valve)

- Material: Stainless steel, brass, or carbon steel.

- End Connections: Threaded or flanged.

Operation: Manual operation with a handwheel for precise flow control. - Features: This valve is typically used for moderate flow regulation and is common in applications like water treatment, HVAC systems, and chemical processing.

2. GENEBRE Type 5200 (Globe Valve with Actuator)

- Material: Stainless steel (AISI 316) body for corrosion resistance.

End Connections: Flanged, threaded, or welded. - Features: Comes with a pneumatic or electric actuator for automated control, making it suitable for more complex systems where remote or automatic operation is necessary.

- Applications: Common in oil and gas pipelines, chemical plants, and industrial control systems.

3. GENEBRE Type 5300 (Forged Steel Globe Valve)

- Material: Forged steel for high-strength applications.

End Connections: Flanged for larger pipes. - Features: Built for high-pressure systems, often used in steam or gas applications.

- Temperature Rating: Can handle higher temperatures and pressures than typical globe valves.

- Applications: Used in power plants, oil refining, and high-temperature chemical processes.

Advantages of GENEBRE Globe Valves

- Flow Control: Ideal for throttling or regulating flow in systems where fine control is necessary.

Leak-tight Shutoff: Globe valves offer a good seal when closed, preventing leakage. - Durability: Made from high-quality materials such as stainless steel, GENEBRE globe valves are durable and can withstand harsh operating conditions.

- Compact Design: Though larger than some other valve types, globe valves generally have a relatively compact design compared to other control valves, making them suitable for confined spaces.

- Versatility: Suitable for both liquids and gases, making them versatile in many industries.

Applications of GENEBRE Globe Valves

- Water Treatment: Globe valves are used to regulate water flow, ensuring proper treatment and distribution.

- Chemical and Pharmaceutical Industries: Ideal for controlling the flow of chemicals or fluids that need to be carefully regulated.

- HVAC Systems: In heating, ventilation, and air conditioning, globe valves control the flow of hot or cold water.

- Oil and Gas: Used in oil refineries, pipelines, and other systems where precise flow control is critical.

- Steam and High-Pressure Systems: GENEBRE globe valves are used to control steam or high-pressure gases in power plants and industrial facilities.

Globe Valve vs. Other Valve Types

- Ball Valves: Unlike ball valves, which are more suited for on/off applications, globe valves excel in precise throttling and regulating flow, though they tend to have higher pressure drop due to the design.

- Gate Valves: Gate valves are used for full flow and are often employed when the valve is either fully open or fully closed. In contrast, globe valves are designed for control and are used when partial flow regulation is required.

- Butterfly Valves: Butterfly valves are also used for flow control but are generally more compact and less precise in regulation compared to globe valves.

GENEBRE CHECK VALVE

A check valve is a type of valve that automatically allows fluid (liquid or gas) to flow in one direction while preventing reverse flow. It is a non-return valve that prevents backflow in a system, which can be crucial in maintaining pressure and preventing damage to equipment or contamination of systems.

How a Check Valve Works

Check valves operate by allowing flow in only one direction. They consist of a valve body, a disc or ball, and a spring (in some models). When fluid flows in the correct direction, the pressure pushes the valve open. If the flow reverses, the valve closes, preventing backflow.

Flow in the correct direction: Fluid pressure pushes the valve's disc or ball away from its seat, opening the valve and allowing flow.

Flow in the reverse direction: If the flow reverses, the fluid pushes the disc or ball against the valve seat, sealing the valve and preventing backflow.

Check valves are typically installed in pipelines to maintain one-way flow, protect pumps from damage caused by backflow, and prevent contamination from reverse flow.

Main Features of GENEBRE Check Valves

GENEBRE's check valves are designed to provide reliable, leak-tight, and efficient operation. Some common features include:

- Materials: GENEBRE check valves are made from stainless steel, brass, carbon steel, and other durable materials, ensuring resistance to corrosion and high-pressure conditions.

Types of Check Valves: GENEBRE produces different types of check valves, including ball check valves, swing check valves, and lift check valves. Each type has its specific advantages depending on the application.

Spring-Loaded and Non-Spring Models: Some check valves from GENEBRE include a spring mechanism to assist in closing the valve, while others rely on fluid flow pressure alone.

Pressure and Temperature Ratings: GENEBRE check valves are suitable for high-pressure and high-temperature applications, offering flexibility for use in demanding industrial environments.

Size Range: GENEBRE offers check valves in various sizes to accommodate different pipe diameters, from small domestic systems to large industrial pipelines.

End Connections: Check valves can come with threaded, flanged, welded, or clamped connections to suit different piping configurations.

Types of GENEBRE Check Valves

GENEBRE produces several types of check valves, each with different mechanisms suited to specific applications:

1. Swing Check Valve

Mechanism: This type of check valve features a disc that swings on a hinge to open and close. When fluid flows in the correct direction, the disc swings open. If the flow reverses, the disc swings back to close the valve and prevent backflow.

Applications: Swing check valves are used in applications where the flow rate is high, such as in water treatment plants, pumping stations, and HVAC systems.

Material: Typically made from stainless steel or cast iron for durability.

Pressure Rating: These are generally designed for medium to high-pressure systems.

2. Ball Check Valve

Mechanism: This type of valve uses a ball that sits in a seat. When fluid flows in the correct direction, the ball is lifted away from the seat, allowing the fluid to pass through. When the flow reverses, the ball is forced against the seat, preventing backflow.

Applications: Ball check valves are often used in applications where the flow rate may vary or where compact designs are necessary.

Material: These valves can be made from brass, stainless steel, or plastic.

Advantages: Compact design and reliable sealing.

3. Lift Check Valve

Mechanism: Similar to a swing check valve, but with a plunger-like disc that moves up and down within the valve body. When the fluid pressure is in the correct direction, it lifts the disc, allowing flow. If the flow reverses, the disc is forced down against the seat to block the flow.

Applications: Used in applications that require high-flow capacity and where backflow prevention is critical.

Advantages: These valves are generally more compact than swing check valves, and they can handle higher pressures in some cases.

4. Y-Type Check Valve

Mechanism: This check valve uses a ball or piston inside the valve body that moves to open and close the valve. It has a Y-shaped design, which makes it ideal for space-constrained applications.

Applications: Common in industries like water and wastewater treatment and oil and gas pipelines.

Advantages: Compact, efficient, and suitable for environments where the space is limited.

Advantages of GENEBRE Check Valves

- Prevention of Backflow: The primary function of a check valve is to prevent reverse flow, which is essential in protecting pumps, compressors, and other equipment.

- Durability: GENEBRE's check valves are made from high-quality materials like stainless steel and brass, ensuring long-lasting performance, even in harsh conditions.

- Versatility: These valves can be used in a wide range of industries and applications, including water treatment, oil and gas, chemical processing, and HVAC.

- Compact Design: GENEBRE offers a variety of sizes and designs to suit different installation spaces, from smaller domestic applications to large industrial systems.

- Leak-tight Sealing: Check valves from GENEBRE are designed to seal tightly and reliably, ensuring no leakage when the valve is closed.

- Ease of Maintenance: Many of GENEBRE's check valves are designed to be easy to maintain and service, reducing downtime and maintenance costs.

Applications of GENEBRE Check Valves

GENEBRE check valves are used in a variety of applications where one-way flow needs to be maintained, and backflow must be prevented. These include:

Water Treatment: Protecting pumps from backflow and maintaining flow in water treatment plants.

Oil and Gas: Preventing backflow in pipelines, compressors, and pumps.

HVAC Systems: Ensuring one-way flow of water or refrigerants in heating and cooling systems.

Chemical Processing: Preventing contamination of chemicals by ensuring that fluids don’t flow back into the system.

Pumping Stations: Protecting pumps from reverse flow that could cause damage or operational failure.

Food and Beverage: Ensuring that liquids or gases flow in the correct direction and maintaining system hygiene.

Pharmaceutical: Preventing contamination in sensitive systems where precise flow control is essential.

GENEBRE BUTTERFLY VALVE

A butterfly valve is a type of valve used to regulate or isolate the flow of fluid in a pipeline. The valve consists of a rotating disc (the "butterfly") that is mounted on a shaft, which turns to either allow or block the flow of fluid. The quarter-turn operation (90-degree rotation) makes butterfly valves easy to operate and ideal for systems that require fast, reliable control.

How a Butterfly Valve Works

The basic working principle of a butterfly valve involves a disc (butterfly) that rotates within the valve body to control the flow of the fluid:

When the valve is fully open, the disc is parallel to the pipe, allowing fluid to flow freely through the valve.

When the valve is closed, the disc rotates 90 degrees (a quarter turn) to a perpendicular position, completely blocking the flow.

Because of this quarter-turn operation, butterfly valves are often preferred for their quick, easy, and reliable control of the flow of liquids and gases in pipelines.

Main Features of GENEBRE Butterfly Valves

GENEBRE’s butterfly valves are designed for reliable performance and versatility across various applications. Here are some of the key features:

Compact Design: Butterfly valves are generally smaller and lighter than other valve types, such as gate or globe valves, making them easier to install and ideal for space-constrained applications.

Wide Range of Sizes: GENEBRE offers butterfly valves in various sizes, from small pipe diameters to large industrial applications.

Material Options: These valves are typically made from stainless steel (AISI 316), cast iron, brass, ductile iron, and plastic for different industrial environments.

End Connections: Available with flanged, wafer, or lug connections to suit different installation needs.

Seals: Seals are typically made of EPDM, NBR, Viton, or PTFE to ensure proper sealing, depending on the fluid and temperature range.

Actuation Options: These valves can be operated manually (with a handle) or automated with pneumatic or electric actuators for remote control or integration into automated systems.

Pressure and Temperature Ratings: GENEBRE butterfly valves are rated for medium to high-pressure and high-temperature applications, depending on the materials used.

Types of GENEBRE Butterfly Valves

GENEBRE offers different types of butterfly valves, depending on the specific application and configuration. The most common types include:

1. GENEBRE Type 7600 (Wafer Butterfly Valve)

Body Material: Ductile iron or stainless steel (AISI 316) for corrosion resistance.

Design: Wafer-style butterfly valve, which is inserted between two flanges without requiring additional end connections. This type of valve is suitable for use in flanged pipelines.

Seal Material: EPDM, NBR, or Viton, depending on the media (water, oil, chemicals, etc.).

Pressure Rating: Typically rated for PN10 or PN16, making it ideal for medium-pressure systems.

Temperature Rating: Usually works in the range of -10°C to 120°C, depending on the seal material.

Applications: Often used in water treatment, HVAC, irrigation, and industrial fluid systems.

2. GENEBRE Type 7500 (Flanged Butterfly Valve)

Body Material: Cast iron or stainless steel.

Design: This valve comes with flanged ends, making it easy to install in systems with standard flanged connections.

Seal Material: EPDM, NBR, or Viton seals for high chemical and thermal resistance.

Pressure Rating: Rated for PN16 (16 bar) applications, making it suitable for medium-pressure systems.

Temperature Range: Typically operates in temperatures ranging from -10°C to 120°C.

Applications: Widely used in industrial piping, water treatment, and chemical distribution systems.

3. GENEBRE Type 7400 (Lug Butterfly Valve)

Body Material: Ductile iron or stainless steel for better mechanical strength and resistance to corrosion.

Design: Lug-style butterfly valve, with threaded lugs on the body. This type allows for easy installation and removal, especially in systems where the valve may need to be isolated.

Seal Material: Available with EPDM, NBR, Viton, or PTFE seals.

Pressure Rating: Rated for PN16 or PN10, depending on the material and size.

Temperature Rating: Suitable for temperatures ranging from -10°C to 120°C.

Applications: Commonly used in water distribution systems, wastewater treatment, chemical pipelines, and fire protection systems.

4. GENEBRE Type 7300 (Manual and Actuated Butterfly Valve)

Body Material: Stainless steel (AISI 316) or brass.

Design: Manual or actuated (pneumatic/electric) valve, allowing for automated operation for remote control of flow.

Seal Material: EPDM, NBR, Viton, or PTFE.

Applications: Ideal for automated flow control in systems that require frequent operation, such as HVAC systems, water treatment, and chemical plants.

Advantages of GENEBRE Butterfly Valves

Compact and Lightweight: Butterfly valves are generally more compact and lighter compared to other valve types, such as gate or globe valves, making them easier to install and handle.

Efficient Flow Control: The quarter-turn operation makes butterfly valves ideal for regulating the flow of fluids in a system quickly and with minimal friction loss.

Low Maintenance: These valves typically have fewer parts than other valve types, making them easier to maintain.

Wide Range of Applications: GENEBRE butterfly valves are used in a variety of industries, including water treatment, food and beverage, chemical processing, oil and gas, and HVAC systems.

Corrosion Resistance: With materials such as stainless steel (AISI 316) and ductile iron, these valves are highly resistant to corrosion and wear, making them suitable for harsh environments.

Versatility: GENEBRE butterfly valves are available in different configurations and sizes, allowing them to be customized for specific needs.

Applications of GENEBRE Butterfly Valves

Water Treatment: Butterfly valves are widely used in water treatment plants to regulate the flow of water and wastewater.

HVAC Systems: Used for regulating airflow in heating, ventilation, and air conditioning systems.

Chemical and Pharmaceutical Industries: Common in chemical plants and pharmaceutical manufacturing for regulating the flow of various chemicals.

Food and Beverage: Used for fluid control in food processing and beverage industries, where hygiene is important.

Oil and Gas: Suitable for regulating flow in pipelines for oil and natural gas distribution.

Irrigation: Butterfly valves are often used in irrigation systems for water flow control.

GENEBRE CONTROL VALVE

A control valve is a device used to regulate the flow, pressure, temperature, or level of fluids in industrial systems.

Key Features of Genebre Control Valves

Precise Regulation:

Genebre control valves offer accurate control of fluid parameters, ensuring efficient system performance.

Robust Construction:

They are built using durable materials like stainless steel, brass, or cast iron, ensuring resistance to corrosion, pressure, and temperature extremes.

Diverse Applications:

Genebre manufactures control valves for a wide range of applications, from simple water flow control to managing complex industrial processes.

Automation Options:

Many Genebre control valves can be equipped with actuators (pneumatic, electric, or hydraulic) for automated operation.

Wide Range of Configurations:

Genebre offers a variety of valve types, including globe valves, ball valves, butterfly valves, and diaphragm valves, catering to different system requirements.

Compliance with Standards:

The valves are typically designed to meet international quality and safety standards.

Types of Genebre Control Valves

Manual Control Valves: Operated by hand, suitable for simpler systems requiring manual intervention.

Automatic Control Valves: Equipped with actuators and controllers for automated operation.

Specialty Valves: Designed for specific applications, such as high-pressure or corrosive environments.

Applications

Industrial Processes: Controlling the flow of chemicals, gases, or steam in factories.

Water Treatment: Regulating water flow in treatment plants.

HVAC Systems: Managing air or water flow in heating and cooling systems.

Oil and Gas: Handling high-pressure fluids and ensuring safety.

Pressure Reducing Valves (PRVs) by Genebre are specialized devices designed to regulate and maintain downstream pressure at a desired level, regardless of variations in upstream pressure.

Key Features of Genebre Pressure Reducing Valves

Accurate Pressure Regulation:

Genebre PRVs ensure precise control of downstream pressure, helping maintain system stability.

High-Quality Materials:

They are manufactured using robust materials such as brass, stainless steel, or cast iron, ensuring durability and resistance to corrosion and wear.

Compact Design:

Genebre designs its PRVs to be compact, making them easy to install in limited spaces.

Versatility:

Suitable for various fluids like water, air, and some gases, depending on the model.

Ease of Adjustment:

The valves feature mechanisms for quick and simple adjustment of the desired downstream pressure.

Low Maintenance:

Genebre PRVs are designed for reliability and require minimal maintenance over their service life.

Compliance with Standards:

These valves meet international quality and safety standards, ensuring performance and reliability.

How Genebre Pressure Reducing Valves Work

Input Pressure: High pressure fluid enters the valve.

Control Mechanism: The valve’s internal components (like a spring and diaphragm or piston) adjust the opening to reduce the pressure to the desired level.

Output Pressure: The regulated, lower pressure fluid exits the valve and flows downstream.

The valve continuously adjusts itself to maintain consistent downstream pressure, even if the inlet pressure fluctuates.

Applications

Water Distribution:

Regulating water pressure in residential, commercial, and municipal systems.

Industrial Processes:

Ensuring stable pressure for machinery and production lines.

HVAC Systems:

Managing pressure in heating, ventilation, and air-conditioning systems.

Irrigation Systems:

Protecting piping and sprinklers by maintaining optimal water pressure.

Genebre offers several models of PRVs, each tailored to specific requirements like flow rate, pressure range, and fluid type. Some common models include:

Brass PRVs for domestic water systems.

Stainless Steel PRVs for industrial or corrosive environments.

Large-Diameter PRVs for high-capacity systems like municipal water networks.